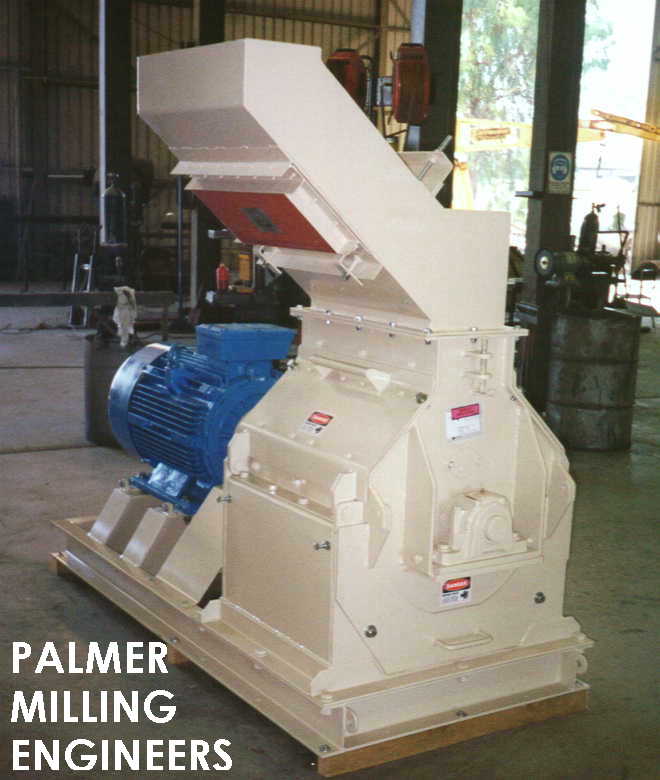

PHM900 hammermill with feedspout, incl. magnet. |

PALMER hammermills are manufactured in several sizes designed to provide the correct grind at the capacity required by the customer.

Full utilisation of the screen area is achieved with the PALMER hammermill. Screens can be easily removed and replaced without the need to stop the hammermill.

The hammermill can be reversed to provide for even wear of hammers.

Screens and hammers are supplied with the hammermill and are designed to give optimum results for the

products being ground.

Hammermills can be supplied with collection hoppers with air filters designed to suit the installation.

|

|

- The following items are supplied standard:-

- Full width product inlet.

- Gravity bottom discharge.

- Dynamically balanced rotor.

- Reversible hammer swing.

- Two access doors, one either side of the machine.

- Nihard gristing plate wear liners.

- Heavy duty bearings.

- 180° grinding screen entry point.

- Hardened pins.

- Direct coupled motor drive, on a common baseplate with hammermill. (Belt drive available)

|

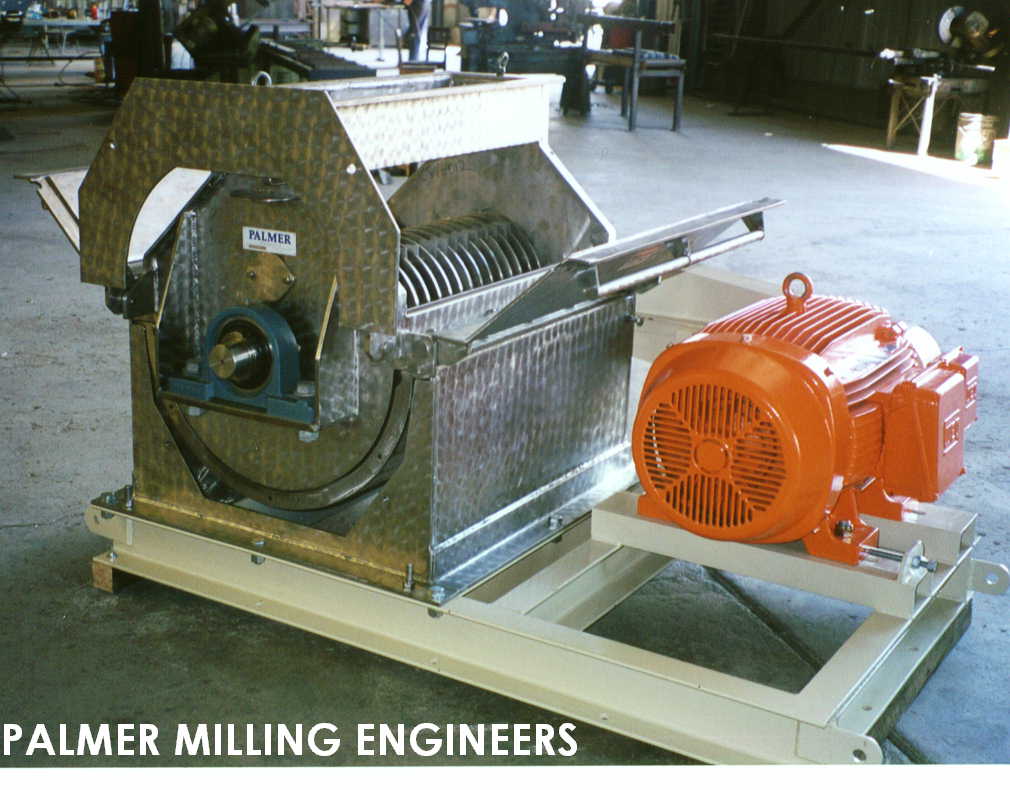

PHM900 full stainless steel hammermill | |

- Optional auxillary equipment:-

- Inlet spout with plate magnet fitted.

- Variable speed screw feeder.

- vibratory feeder.

- Collection hopper fitted with:

- Air filter and fan.

- Discharge conveyor.

- Rotary seal.

- Access platform with ladder.

|

PHM900 hammermill |